Industrial Rotopactor Machine

500000.00 - 1250000.00 INR/Piece

Product Details:

- Product Type Rotopactor

- General Use Yes

- Type Gear Grinding Machine Surface Grinding Machine

- Capacity High

- Computerized No

- Automatic No

- Power 120 Horsepower (HP)

- Click to View more

X

Industrial Rotopactor Machine Price And Quantity

- 500000.00 - 1250000.00 INR/Piece

- 1 Piece

Industrial Rotopactor Machine Product Specifications

- 120 Horsepower (HP)

- 440 Volt (v)

- High Performance

- Yes

- No

- No

- Yes

- High

- Rotopactor

- Gear Grinding Machine Surface Grinding Machine

Industrial Rotopactor Machine Trade Information

- Cash in Advance (CID) Cheque

- 1 Piece Per Week

- 1 Week

- Western Europe Australia North America South America Eastern Europe Middle East Central America Asia Africa

- All India

Product Description

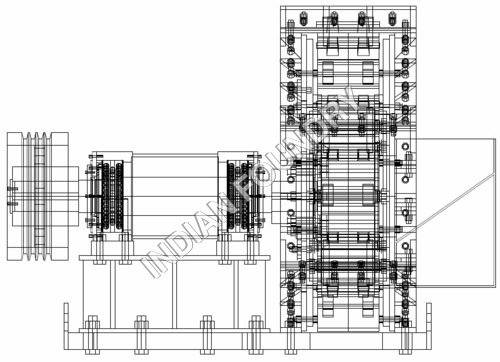

RotopactorsWe offer a wide range of Rotopactor at affordable prices. Authentic steel is sourced from some of the known vendors of the industry. Thus, a sturdy and durable body is manufactured. It is primarily used for the purpose of crushing stones in the industrial sector. Rotopactor machines are appreciated for the high grade finishing these provide. We can customize these machines in terms of sizes, as per the clients specifications.

Rotopactor

Our Rotopactor, basically a rotary crusher used in the secondary or tertiary stage of a stone crushing plant, is the ultimate weapon against flakiness.

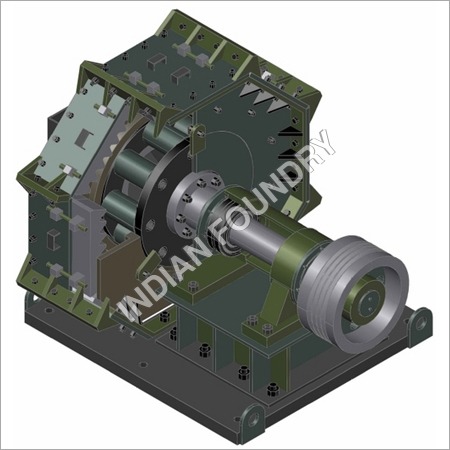

Its sturdy design consists of an impeller (Rotor) rotating at 1000-1200 r.p.m. inside a steel fabricated body lined with high grade austenitic manganese steel breaker liners.

The stone to be crushed is fed directly into the centre of the rotor, the high rotating speed of which throws the material outwards towards the breaker liners and other flying crushed particles for further impact crushing. The result of the process is production of absolutely cubically crushed stone, which finds great use in the construction sector.

Use our Rotopactor and cut crushing costs !!!

The rotor is completely dis-assemble and hence all its components - back plate,

eight rollers and ring (all of manganese steel casting) can be individually replaced to avail optimum useful life.

The direction of rotation of the rotor can be reversed to prolong the useful life of the

same as well as the breaker liners, thereby reducing the cost of crushing.

None of the components requires frequent adjustment like in a jaw crusher, roll crusher

or cone crusher and hence the down time is very less.

Hopper of the Rotopactor is so designed that when it is fed for the first time, a bed of

stones is formed inside it. The material fed further falls on this bed and does not hit the bottom plate of the hopper directly. Hence wear and tear is minimized.

Hinged design of the hopper enables faster access inside the main body, thereby

reducing consumables replacement time.

Enter Buying Requirement Details